When a sleek white box wobbles onto a city sidewalk, wheels turning in a silent shuffle, and a familiar logo flashes onto the lid, most observers simply see a new piece of street‑level technology. In reality, those wheels are powered by one of the most reliable yet often overlooked components in modern robotics: the gear or reducer motor.

The recent surge of autonomous delivery robots (ADRs) across downtowns in New York, London, and Singapore has turned the streets into a living laboratory. What started as a handful of experimental robots testing sidewalk turbulence has grown into a distributed network of over 50 000 units in North America alone, as reported by TechCrunch and corroborated by city council press releases. The trend is not only an engineering triumph but also a response to consumer demand for faster, contactless delivery—and to the growing need for green logistics solutions as cities tighten carbon‑neutral targets. To keep pace with this momentum, manufacturers look to components that combine durability, compactness, and efficiency. Gear motors fit that bill perfectly.

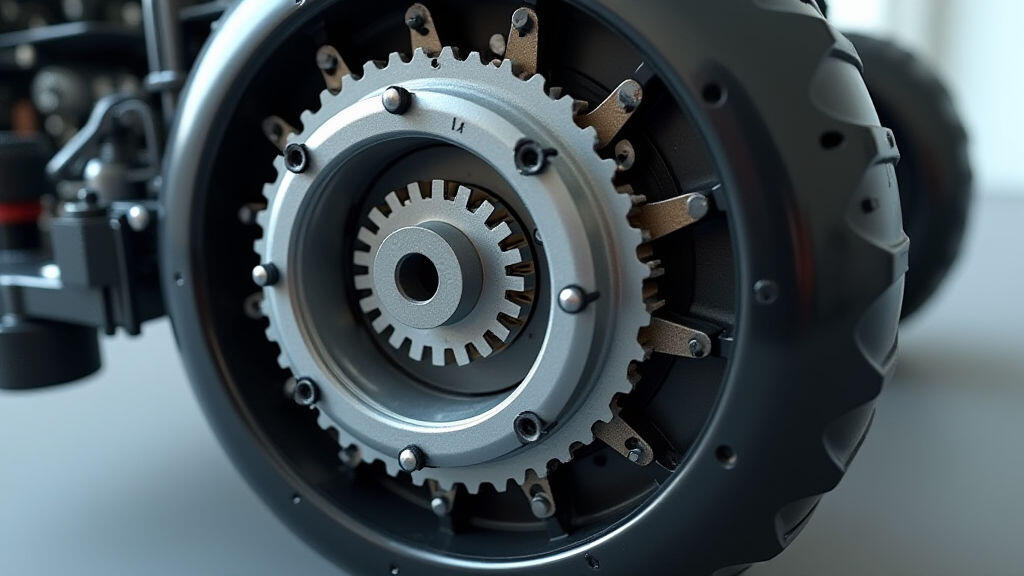

At a glance, ADRs may seem like just additional wheels and a smart controller. In truth, they are complex systems where mechanical motion meets AI decision‑making. Gear motors—specifically low‑speed, high‑torque type reducers—act as the muscle that translates electrical braking into intentional movement, steering, and obstacle interaction.

Unlike brushless DC motors that specialize in high speed, gear motors are engineered to provide significant torque at lower speeds—a requirement for the heavy-duty tasks ADRs perform. Those tasks include:

Industry analysts from IC Insights estimate a compound annual growth rate (CAGR) of 12 % for automotive and robotics application of reducer motors between 2025 and 2032, driven by the autonomous cargo market. Vendor diversification means that ADR operators need interchangeable parts to maintain service uptime. Gear motors meet this demand thanks to their:

Beyond azimuthal industrial applications, the ADR market is essentially forcing a shift from total gearless systems toward hybrid architectures that combine brushless speed‑regulation with gearhead torque amplification. The result is a more flexible product line capable of thriving in diverse socio‑economic environments—from the payload‑heavy city canyons of Manhattan to the fluid streets of emerging Southeast Asian cities.

Lead manufacturers are now embedding sensors directly into gear motor assemblies. 3 mm micro‑encoders track joint angle precisely, while temperature sensors monitor core heating. These data streams integrate with AI algorithms running onboard, enabling real‑time torque adjustment and predictive maintenance. The modern gear motor is semi‑autonomous; it no longer merely follows a command, it optimizes effort in response to real‑world conditions.

This capability has amplified the safety profile of ADRs—a prevailing public concern highlighted in the flagship CityDoc 2025 Report that called for “highly reliable, self‑monitoring operating systems” for street‑level robots. Gear motors now fulfill that requirement as they facilitate adaptive braking and torque modulation.

Looking ahead, the integration of solar panels or kinetic energy harvesters into ADR chassis will make power supply more autonomous. Gear motors, with their lower losses under variable load, become the logical match for such hybrid power architectures. In addition, the move toward electric vehicles for logistics drones and parcel vans will see a cross‑pollination of gear motor技术—adapting from robotics to electric freight.

On the policy front, governments are planning to end the “heavy‑congestion” zone usage of delivery robots. The shift demands better torque management to lessen wear on pavements and the motors themselves. Gear motors can offer the superior torque‑to‑size ratio that reduces wheel slip, thus preserving road integrity—a win‑win for municipalities aiming to maintain city infrastructure while embracing innovation.

The autonomous delivery robot revolution has catapulted gear motors from a background component to the linchpin of urban logistics. These high‑torque, low‑speed reducers enable robots to move reliably, handle variable loads, and maintain safety standards that the public demands. They respond to industry pressure for sustainability through improved efficiencies and a modular design that encourages longevity. As cities pivot toward greener future‑ready infrastructures, gear motors—quiet, robust, and increasingly intelligent—will remain the foundational engine driving that transformation.

In a world where the next step of urban mobility is already on our sidewalks, consider the humble gear motor’s crucial role: it turns electricity into motion, turning the imagination of autonomous delivery into everyday reality.

Leave A Reply

Your email address will not be published. Required fiels are marked